A company’s supply chain is a set of activities or operations involved in carrying out the process of selling a product in its entirety. These activities range from supervision, the process in which raw materials are obtained, the manufacture of products, production, distribution, transport and delivery of these.

One of the objectives to achieve by a factory or company is to satisfy in the best possible way the needs of an end user or customer. Thus, the main objective of a supply chain is to provide the items and materials in quantity, quality and time needed at the lowest possible cost. Within this we can find others such as:

Establish good communication channels.

To have an adequate coordination.

Avoid unnecessary losses.

Improve distribution times.

Adapt inventory management.

Respect delivery times.

Respond effectively to changes in demand and supply.

The main thing is to keep it dynamic, that is to say that there is a continuous flow of information of all the process of obtaining and manufacture. In addition, in the different stages it is necessary to maintain all relationships with suppliers, wholesalers, and customers, controlled to obtain a refined dynamic.

Some of the Mayor Points in the Supply Chain

Quality

The more complex the supply chain, the more actors are involved in it. It is therefore more difficult to ensure that they maintain the required quality standards over time. In addition, suppliers have other suppliers at the same time, which again represent an additional factor of uncertainty.

Inventory

Inventory management is an art, which once again becomes exponentially more complex the longer the supply chain. As they become longer and longer, the amount of inventory that companies have to manage increases.

Losses in transit & Returnable Assets

The loss of goods during transport is another major concern. The casuistry is infinite: from small incidents to the complete loss of a vehicle or carrier shipment (see the containers that were lost at sea), reaching extreme cases such as the hijacking of ships by pirates. And its consequences: economic losses, problems with insurance, delays in deadlines, paperwork with insurance, etc.

Most returnable assets in the supply chain are not tracked, or are only tracked manually, a process which creates inefficiencies and economic loss due to low return rates, delays and high costs associated with tracing these items. As a result, a large amount of assets are not circulated back to owners, and instead are either given to competitors or are inefficiently recycled or disposed.

Creating New Trust

As Dom Schiener (Co-Founder of IOTA) said in his presentation at the Bosch Connectivity event, the supply chain is a black box, we consumers and businesses have no idea what the process was that had to go through our mobile phone to be in our hands today, and it’s more than valid, we just care that the device works well. However, this interest would change if as consumers we talked about a product that is directly related to the risk to our health or life, we would like to be sure that the product we are going to use is made with the best materials and that those materials respected a process until reaching the company that assembles or manufactures them. We are never too cautious when it comes to that.

Now, most of the world’s supply chains still pour their data on paper, which we know can be easily altered or lost anywhere in the process, so the veracity of many of the data exchanged has no other validation than trust in the person who recorded the data. A new digital infrastructure is needed to change this is where a DLT like IOTA appears as a solution. With IOTA Tangle Technology we can rely on what is happening throughout the Supply Chain process.

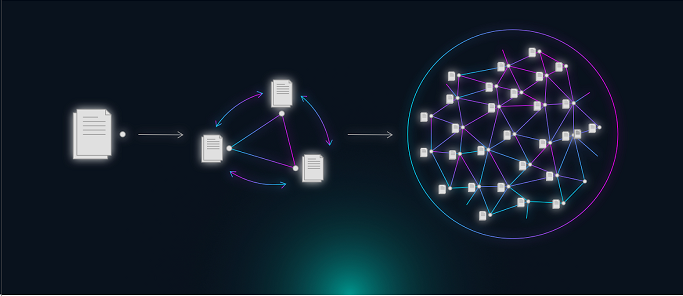

A distributed ledger is a consensus of replicated, shared, and synchronized digital data geographically spread across multiple sites, countries, or institutions.There is no central administrator or centralized storage data. A peer-to-peer network is required as well as consensus algorithms to ensure replication across nodes is undertaken.

A Distributed Ledger Like IOTA Allows to:

Digitize the whole process and not only digitize it, but also make it cryptographically secure, so that it cannot be altered.

With a Distributed Ledger the different events that occur along the Supply Chain can be collected and sent to the TANGLE, being able to ensure the entire chain of custody.

Processes that were previously manual can now be fully automated. DLT’s are creating a single version of the truth since the information that is uploaded to TANGLE cannot be altered, so we can trust that the information that is uploaded is completely reliable. No more risk of losing thousands and thousands of dollars by depending on a system that allows the alteration of data at any point in the process of a product.

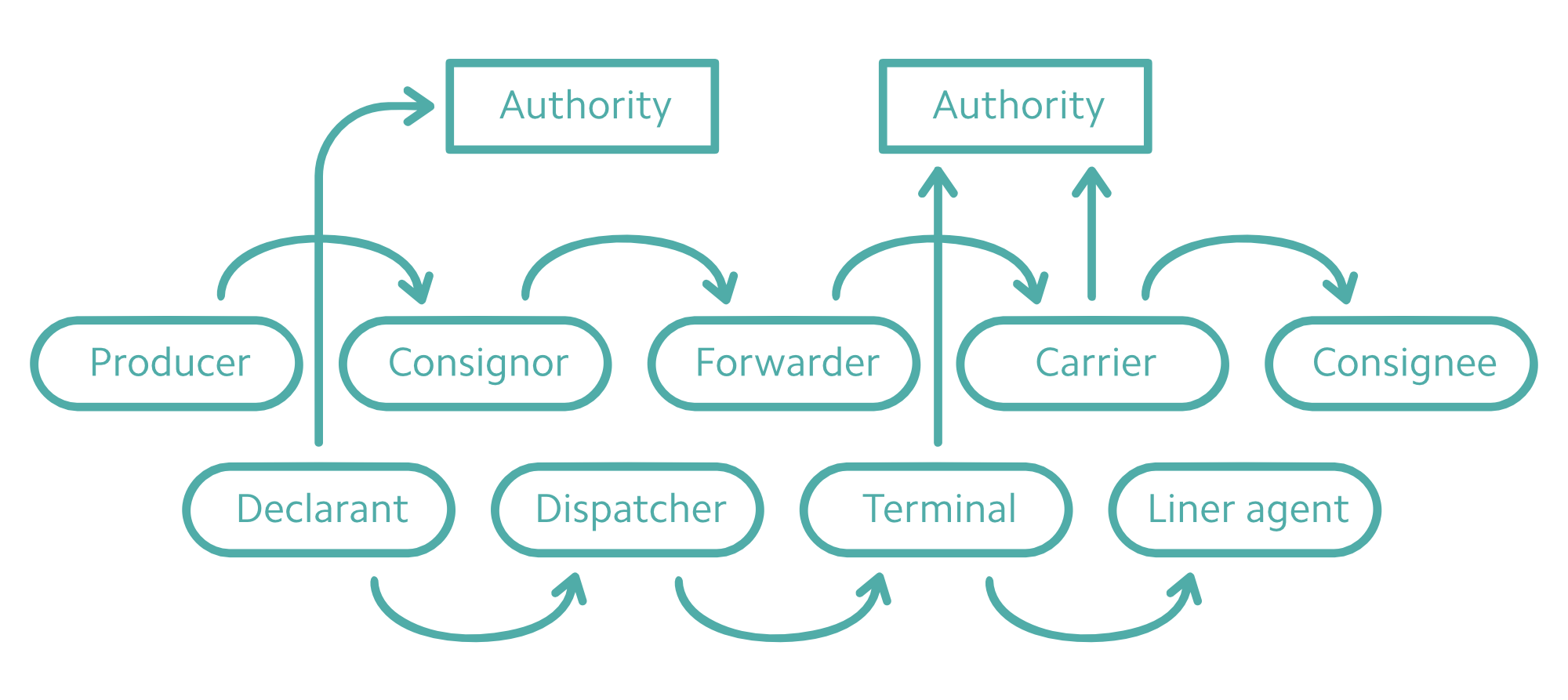

The information is no longer bi-directional, rather than based on triplicate documents that are sent to different actors within the chain, through the DLT’s the data will be an open, transparent and collaborative network, where each actor in this supply chain will be able to upload verifiable data to TANGLE and start sharing this data with specific parties involved in the Supply Chain.

The IBCS Poland Proof of Concept (PoC)

The IBCS Poland Proof of Concept (PoC) is yet another concrete example of IOTA’s vision for enabling the Global Trade and Supply Chain.

The IOTA Foundation announced that its open source Tangle technology and MAM (Masked Authenticated Messaging) protocol will support IBCS Poland with a solution for tracking and tracing assets in the supply chain. The goal of the IOTA solution is to help IBCS Group customers improve the planning of their deliveries and shipments, through an open source IOTA Track and Trace application as a starting point, which is available for companies to start building tracking solutions for their markets.

To remedy the problems of Returnable Assets, the IOTA-driven solution will provide a unique digital identity for each asset, including the position and identity of the organization that currently has custody of it, all of which can be viewed and managed through a simple mobile application.

As a result, companies can get an accurate overview of the assets available for shipment anywhere, anytime, which translates into more efficient delivery planning, lower administrative burden, and higher profits. The solution that works with IOTA will not require integration with different legacy systems or a centralized repository. This means that customers can securely view and request the return of assets for reuse, without sharing any confidential or confidential information with competitors who also have assets circulating within the same supply chain ecosystem.